- Eng

- Deu

- Fra

Top 10 Benefits of Using Rotary Vane Vacuum Pumps for Your Applications

The utilization of rotary vane vacuum pumps has become increasingly prevalent across various industries, owing to their unique design and performance advantages. According to a recent report by MarketsandMarkets, the vacuum pump market is expected to reach USD 3.88 billion by 2026, driven by the growing demand for efficient vacuum solutions in applications such as food packaging, pharmaceuticals, and semiconductor manufacturing. The rotary vane vacuum pump, in particular, stands out with its ability to provide consistent and reliable vacuum levels, essential for critical industrial processes.

One of the key benefits of rotary vane vacuum pumps is their versatility and adaptability. These pumps are capable of handling a wide range of applications, from industrial processes to laboratory settings, ensuring that users can rely on them for various needs. Moreover, data from the American Vacuum Society indicates that rotary vane vacuum pumps offer significant energy efficiency, with lower operating costs compared to traditional vacuum pump technologies. As industries continue to seek sustainable and cost-effective solutions, rotary vane vacuum pumps will undoubtedly play a crucial role in shaping the future of vacuum technology.

Top Benefits of Rotary Vane Vacuum Pumps for Industrial Applications

Rotary vane vacuum pumps are becoming increasingly popular in various industrial applications due to their unique advantages. One of the primary benefits is their ability to deliver consistent and reliable vacuum levels, making them ideal for processes that require precise control over vacuum conditions. According to a report by the International Vacuum Technology Association, rotary vane pumps can achieve ultimate vacuum levels as low as 0.5 mbar, ensuring optimal performance for applications like packaging, food processing, and pharmaceuticals where maintaining product integrity is paramount.

In addition to their performance, rotary vane vacuum pumps are renowned for their energy efficiency. Recent studies indicate that these pumps can operate at a significantly lower energy consumption rate compared to traditional vacuum technologies, with some estimates suggesting energy savings of up to 30%. This not only helps reduce operational costs but also aligns with sustainability goals that many industries are pursuing. The design and engineering of rotary vane pumps allow for reduced maintenance needs and longer service intervals, which further contribute to their cost-effectiveness and make them a smart investment for industrial applications.

Top 10 Benefits of Using Rotary Vane Vacuum Pumps for Your Applications

| Benefit | Description | Application Areas |

|---|---|---|

| High Efficiency | Rotary vane vacuum pumps are designed for high efficiency, reducing energy costs. | Manufacturing, Packaging |

| Low Maintenance | These pumps require minimal maintenance, which saves time and operational costs. | Food Processing, Pharmaceutical |

| Compact Design | Small footprint allows for easy integration into confined spaces. | Laboratories, Small Workshops |

| Versatility | Can handle various applications including both liquid and gas evacuation. | Chemical Processing, Aquaculture |

| Quiet Operation | Designed to operate quietly, making them suitable for noise-sensitive environments. | Hospitals, Research Labs |

| Consistent Performance | Maintains performance over time with minimal variation. | Industrial Processes, Automation |

| Robust Construction | Durable materials ensure long service life and reliability. | Heavy Industry, Mining |

| Cost-Effective | Lower initial purchase and operational costs compared to other types of pumps. | Startups, Small Business Operations |

| Oil-Free Options | Some models are oil-free which is ideal for critical applications. | Electronics, Medical Equipment |

| Easy to Use | User-friendly controls make them accessible for operators of all skill levels. | Workshops, Academic Institutions |

Energy Efficiency: Analyzing Power Consumption and Performance Stats

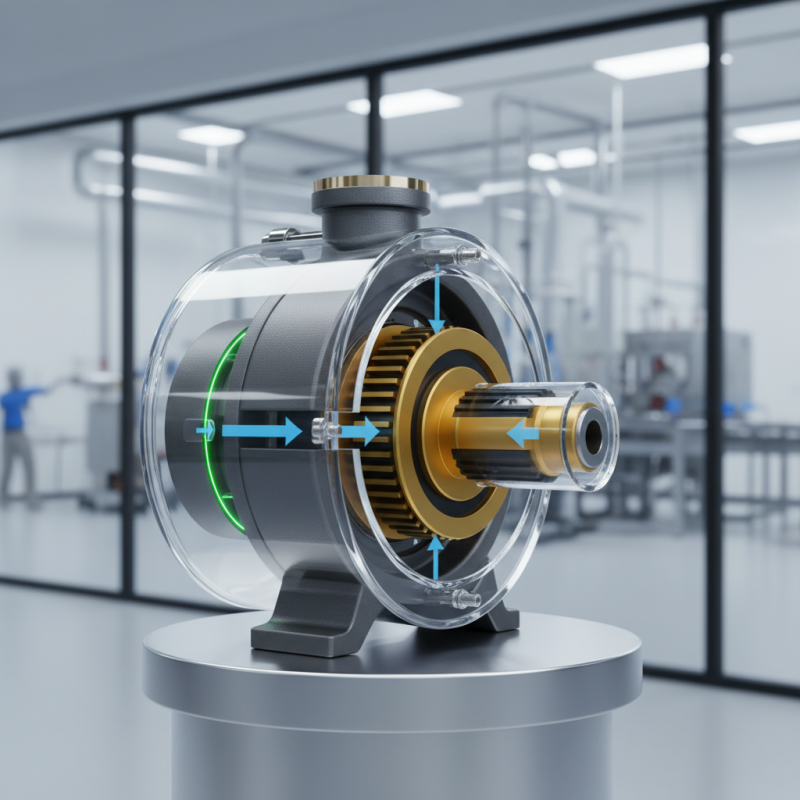

Rotary vane vacuum pumps are an excellent choice for various applications due to their energy efficiency. These pumps operate using a series of vanes that rotate within a cylindrical chamber, creating a vacuum by trapping and compressing air. This design allows for consistent performance while maintaining low power consumption. Analyzing power consumption and performance stats reveals that rotary vane pumps can typically achieve high efficiency levels, meaning lower electricity bills and a reduced environmental footprint.

Tips for maximizing energy efficiency with rotary vane vacuum pumps include regular maintenance and ensuring optimal operating conditions. By monitoring the system’s performance and keeping components clean, users can prevent unnecessary energy loss. Additionally, it's essential to match the pump size to the application's needs, as an oversized pump can lead to increased power consumption.

Furthermore, investing in a variable speed drive can enhance energy efficiency by adjusting the pump speed according to demand. This adaptability not only optimizes performance but also improves longevity and minimizes wear. By implementing these practices, businesses can leverage the benefits of rotary vane vacuum pumps while maintaining sustainable operational practices.

Operational Reliability: Examining Downtime and Maintenance Frequency

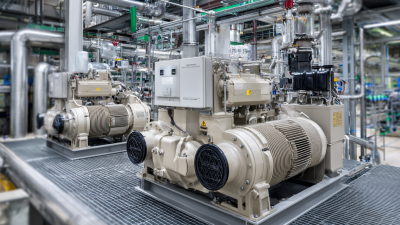

Operational reliability is a critical factor when considering the maintenance and performance of rotary vane vacuum pumps. These pumps are known for their robust construction and ability to handle a variety of applications with minimal downtime. Unlike other vacuum systems, rotary vane pumps are designed to operate continuously, making them ideal for processes that require a stable vacuum. Their efficient design minimizes wear and tear, leading to reduced maintenance frequency and longer operational life.

To enhance the reliability of your rotary vane vacuum pump, regular maintenance checks are essential. Here are some tips to keep your pump in optimal condition: regularly inspect the oil level and quality, as proper lubrication is key to minimizing friction and wear. Additionally, monitor the pump for unusual noises or vibrations, as these may indicate underlying issues. Maintaining a clean environment around the pump can also help prevent dust and debris from entering the system, further reducing the need for frequent repairs.

Another advantage of rotary vane vacuum pumps is their simplicity, which translates into lower maintenance costs. With fewer moving parts compared to other types of vacuum pumps, they are less prone to failure. Ensuring that the pump's filters are changed according to the manufacturer’s recommendations can also reduce maintenance frequency. A proactive approach to maintenance not only extends the lifespan of rotary vane vacuum pumps but also ensures continuous operational reliability, making them a smart choice for many industrial applications.

Versatility in Applications: Industries Utilizing Rotary Vane Pumps

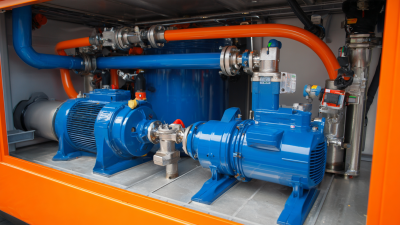

Rotary vane vacuum pumps are celebrated for their versatility across various industries. These pumps are employed in sectors such as food packaging, pharmaceuticals, and electronics manufacturing, where creating and maintaining a vacuum is vital for preserving product integrity and enhancing operational efficiency. According to a report by Persistence Market Research, the global vacuum pump market is expected to grow at a CAGR of 5% from 2021 to 2028, indicating an increasing reliance on technologies like rotary vane pumps.

In the food industry, rotary vane pumps facilitate vacuum sealing processes, extending the shelf life of perishable goods while maintaining freshness. In the pharmaceutical sector, these pumps ensure that sterile environments are upheld during production, thereby minimizing contamination risks. Further, in electronics manufacturing, they are critical in creating vacuums for degassing and drying processes, which are essential for high-quality product output.

When selecting a rotary vane vacuum pump for your application, it is essential to consider factors such as pump efficiency, maintenance requirements, and compatibility with the materials involved. Tips for ensuring optimal performance include regular maintenance checks to prevent wear and tear and utilizing the pump within its specified operational range to avoid overheating. Additionally, consulting technical specifications and data can help ensure the chosen pump aligns with the unique requirements of your industry.

Cost-Effectiveness: Evaluating Long-Term Savings and ROI in Operations

When considering the integration of rotary vane vacuum pumps into industrial applications, one of the most compelling aspects is their long-term cost-effectiveness. Recent industry reports indicate that rotary vane pumps can significantly reduce operational costs due to their lower energy consumption compared to other pump types. According to a comprehensive analysis by the Vacuum Technology Association, these pumps can lead to energy savings of up to 30% annually, primarily due to their efficient design and reliable performance. This efficiency not only contributes to lower electricity bills but also minimizes the environmental impact of operations.

In addition to energy savings, the durability and low maintenance requirements of rotary vane vacuum pumps enhance their return on investment (ROI). A study published by the International Journal of Vacuum Science highlights that businesses can experience a ROI of 150% within the first three years of using rotary vane pumps, thanks to decreased maintenance costs and extended service life. With a lifespan that often exceeds 10 years with proper care, these pumps allow companies to allocate resources more effectively, focusing on growth and innovation rather than equipment downtime.

The combination of energy efficiency, low maintenance, and longevity positions rotary vane vacuum pumps as a savvy investment choice for industries looking to optimize their operations while ensuring cost-effectiveness.

Conclusion

Rotary vane vacuum pumps offer a multitude of benefits for industrial applications that make them a preferred choice for many industries. Their energy efficiency is noteworthy, as they balance power consumption with high performance, reducing operational costs. Additionally, these pumps exhibit remarkable operational reliability, resulting in minimal downtime and lower maintenance frequency, which further enhances their cost-effectiveness and overall return on investment (ROI).

The versatility of rotary vane vacuum pumps allows them to be utilized across various sectors, demonstrating their adaptability to different applications. Moreover, their role in promoting sustainability is evident, as they contribute to emission reductions and have a positive environmental impact. Overall, incorporating rotary vane vacuum pumps into operations not only supports efficiency and reliability but also aligns with modern sustainability goals.

Related Posts

-

Understanding the Science Behind Rotary Vane Vacuum Pumps for Industrial Applications

-

Understanding the Essential Performance Metrics of Rotary Vane Vacuum Pumps for Optimal Industrial Applications

-

Understanding the Importance of Septic Vacuum Pumps for Effective Waste Management Systems

-

What is an Oil Vacuum Pump and How Does it Work for Efficient Operations

-

10 Essential Tips for Choosing the Right Vacuum Blower Pump for Your Needs

-

Why Oil Pumps Are Essential for Efficient Fluid Management in Industrial Applications