- Eng

- Deu

- Fra

How to Choose the Right Oil Pumps for Your Industrial Needs

Choosing the right oil pumps for industrial applications is a critical decision that can significantly impact operational efficiency and cost-effectiveness. As John Carter, a renowned expert in fluid dynamics and a consultant for various industrial sectors, succinctly puts it, “The right oil pump can make all the difference in ensuring seamless operations and prolonging machinery life.” This statement underscores the importance of selecting the appropriate oil pumps tailored to specific industrial needs.

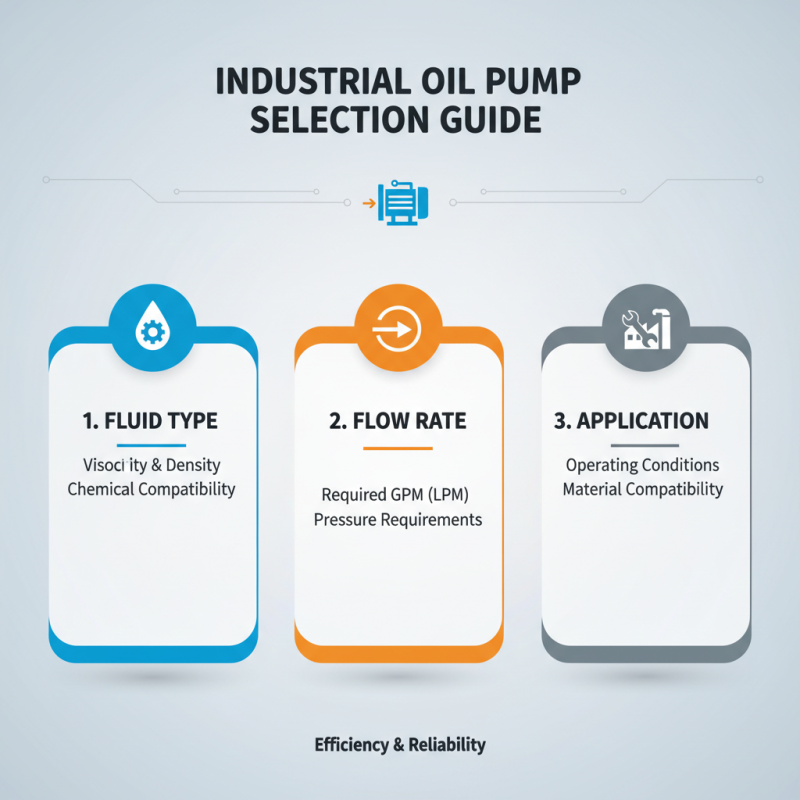

The variety of oil pumps available on the market can be overwhelming, but understanding key factors such as application requirements, flow rates, and compatibility with fluids can simplify the selection process. Whether for enhancing the performance of hydraulic systems or facilitating the transfer of lubricants, the right oil pumps not only optimize efficiency but also minimize maintenance issues and operational downtime. By navigating through the complexities of oil pump selection, industries can ensure smoother workflows and greater productivity.

Understanding Different Types of Oil Pumps Available in the Market

When selecting the appropriate oil pump for industrial applications, it is crucial to understand the various types available in the market. Oil pumps can be broadly categorized into positive displacement pumps and centrifugal pumps. Positive displacement pumps, which include gear, diaphragm, and screw pumps, operate by trapping a fixed amount of oil and forcing it through the discharge. This mechanism is ideal for high-viscosity fluids and applications requiring a consistent flow rate, making them a favorite in sectors like manufacturing and chemical processing.

On the other hand, centrifugal pumps utilize rotational energy to move oil, making them more suitable for low-viscosity fluids and applications where high flow rates are necessary. According to a report by the Global Market Insights, the oil pump market is projected to surpass USD 5 billion by 2026, with a steady annual growth rate attributed to the rising demand in the oil & gas industry and increasing investments in infrastructure development. Moreover, advancements in technology, such as the introduction of smart pumps equipped with IoT capabilities, are revolutionizing efficiency and monitoring in oil transport and distribution, further diversifying the options available to industrial consumers.

Therefore, a thorough assessment of your specific needs, including fluid characteristics, system requirements, and pump efficiency, is essential to ensure the selection of a suitable oil pump that enhances operational performance.

Oil Pump Types and Their Applications

Key Factors to Consider When Selecting an Oil Pump for Industrial Use

When selecting an oil pump for industrial use, there are several key factors to consider. Firstly, understanding the specific requirements of your application is crucial. This includes the type of oil being pumped, its viscosity, and the required flow rate. Different oils have varying densities and consistencies, which can impact pump performance. Ensure that the chosen pump is compatible with the fluid properties to prevent operational issues and ensure efficiency.

Another critical aspect is the pump’s design and construction materials. Pumps come in various designs, such as gear, diaphragm, or centrifugal, each suitable for different applications. In addition, the materials used in the construction of the pump should be resistant to corrosion and wear, especially if the oil being pumped contains additives or contaminants. Evaluating the environmental conditions in which the pump will operate, including temperature fluctuations and the presence of hazardous substances, can help in choosing a durable and long-lasting solution.

Lastly, consider the maintenance and operational costs associated with the oil pump. Look for pumps that offer ease of maintenance, as this can significantly reduce downtime and service expenses over time. Additionally, energy efficiency plays a vital role in the overall cost-effectiveness of your operations, so select a pump that minimizes energy consumption while meeting performance standards. Balancing these factors will lead to a more informed decision in selecting the right oil pump for your industrial needs.

Evaluating Pump Performance Metrics: Flow Rate, Pressure, and Efficiency

When selecting oil pumps for industrial applications, understanding performance metrics is crucial. Three primary metrics to consider are flow rate, pressure, and efficiency. According to a recent industry report from the Hydraulic Institute, flow rate is often the first consideration, typically measured in gallons per minute (GPM). For example, a pump with a flow rate of 500 GPM can facilitate significant volume transport, making it ideal for high-demand scenarios. However, it's important to choose a pump that matches not only the required flow rate but also the system's pressure requirements to ensure optimal operation.

Pressure metrics are equally important, as they determine how effectively a pump can move fluids through a system against resistance. The American Society of Mechanical Engineers (ASME) states that maintaining the correct pressure levels is essential for avoiding cavitation and ensuring longevity of equipment. A pump operating at its optimal pressure range can enhance system reliability, leading to lower maintenance costs and reduced downtime. Additionally, efficiency is a key performance indicator, often expressed as a percentage indicating the ratio of hydraulic power output to mechanical power input. According to the DOE's Energy Efficiency Program, pumps with efficiencies above 85% can significantly reduce energy consumption and operational costs, underscoring the importance of selecting the right pump for specific industrial needs.

How to Choose the Right Oil Pumps for Your Industrial Needs - Evaluating Pump Performance Metrics

| Pump Type | Flow Rate (GPM) | Pressure (PSI) | Efficiency (%) | Power (HP) |

|---|---|---|---|---|

| Gear Pump | 20 | 150 | 85 | 5 |

| Rotary Vane Pump | 35 | 120 | 90 | 7.5 |

| Centrifugal Pump | 50 | 100 | 75 | 10 |

| Diaphragm Pump | 15 | 200 | 80 | 3 |

| Progressing Cavity Pump | 25 | 180 | 88 | 6 |

Assessing Compatibility with Your Fluid Types and Operating Conditions

When selecting the right oil pumps for industrial applications, it is crucial to assess the compatibility with the specific fluid types and operating conditions present in your system. Different fluids exhibit varied properties such as viscosity, temperature stability, and corrosiveness, all of which can impact the performance and longevity of the pump. For instance, a fluid with high viscosity may require a pump designed for thicker substances, while aggressive chemicals may necessitate materials that resist corrosion to avoid degradation of the pump components.

Equally important are the operating conditions under which the pump will function. Factors such as temperature variations, pressure levels, and the potential for abrasive particles in the fluid should be carefully evaluated. In high-temperature environments, pumps that can maintain efficiency without compromising their integrity become essential. Additionally, if the operating environment poses risks such as pulsating flow or cavitation, choosing a pump with built-in features to mitigate these issues can significantly enhance the reliability of your system.

By thoroughly analyzing these aspects, industries can ensure that their selected oil pumps not only meet performance expectations but also maintain operational efficiency over time.

Maintenance and Support Considerations for Industrial Oil Pumps

When selecting an oil pump for industrial use, it's crucial to prioritize maintenance and support considerations. Regular maintenance can significantly extend the lifespan of the pumps and ensure they operate at maximum efficiency. A well-maintained oil pump can reduce energy consumption and prevent unexpected breakdowns that lead to costly downtime.

It is essential to establish a maintenance schedule that includes routine checks, lubrication, and parts replacement as needed.

Tips: Keep a detailed maintenance log for each pump. This will help track performance issues and ensure that all scheduled maintenance is performed on time. Additionally, invest in training for your operational staff to recognize early signs of wear or malfunction, which can aid in timely interventions.

Support considerations are equally vital. Choose a supplier that offers reliable technical support and access to spare parts. In the event of a malfunction, having a support system in place helps you to resolve issues swiftly and minimizes disruption to your operations. It’s beneficial to understand the warranty and post-purchase support options available, ensuring that any repairs or replacements can be handled efficiently.

Tips: Establish a direct line of communication with your supplier to quickly access technical assistance when needed. This relationship can also provide valuable insights into optimizing oil pump operation tailored specifically to your industry requirements.

Related Posts

-

Why Oil Pumps Are Essential for Efficient Fluid Management in Industrial Applications

-

Understanding the Future of Energy: How Oil Pumps Power the Transition to Renewable Resources

-

How to Effectively Pump Oil for Maximum Efficiency and Safety

-

Understanding the Essential Performance Metrics of Rotary Vane Vacuum Pumps for Optimal Industrial Applications

-

2025 Top 5 Suction Pumps: Best Picks for Efficiency and Reliability

-

Exploring Vacuum Oil: Key Benefits and Industry Trends Influencing Machinery Performance