- Eng

- Deu

- Fra

How to Effectively Pump Oil for Maximum Efficiency and Safety

In the realm of energy production, the process of pumping oil stands as a critical operation that demands attention to both efficiency and safety. As the global demand for petroleum products continues to rise, optimizing the methods used to pump oil has become vital not only for maximizing production rates but also for ensuring the safety of personnel and the environment. The intricate balance between these two aspects underpins the effectiveness of oil pumping strategies and technologies.

Effective oil pumping involves a combination of advanced techniques, innovative equipment, and adherence to strict safety protocols. From maintaining the integrity of the pumping equipment to ensuring that safety measures are in place for handling volatile substances, each element plays a significant role in achieving optimal outcomes. This discussion highlights the importance of understanding the intricacies of oil pumping systems, which can lead to improved operational practices and reduced risks.

As we dive deeper into the various methods and best practices for pumping oil, it becomes clear that fostering a culture of safety while striving for peak efficiency is imperative. By prioritizing these principles, oil companies can enhance their productivity, mitigate potential hazards, and contribute to a sustainable energy future.

Understanding Oil Pumping Basics: Types and Functions

When it comes to oil pumping, understanding the different types and their specific functions is crucial for ensuring both efficiency and safety. The primary types of oil pumps include gear pumps, diaphragm pumps, and screw pumps.

Gear pumps utilize two meshing gears to transfer oil, providing a high flow rate with minimal pulsation. They are often used in applications requiring consistent pressure, making them ideal for hydraulic systems.

Diaphragm pumps, on the other hand, operate by alternately flexing a diaphragm to create a vacuum and draw oil into the pump chamber. This type of pump is highly effective for handling viscous fluids, as they can accommodate varied oil densities without significant efficiency loss.

Finally, screw pumps, characterized by their helical screw mechanism, offer smooth and continuous flow, allowing for precise control over the oil delivery. Each type of pump has its unique advantages, and selecting the right one depends on the specific requirements of the application, including the type of oil being pumped and the required flow rate.

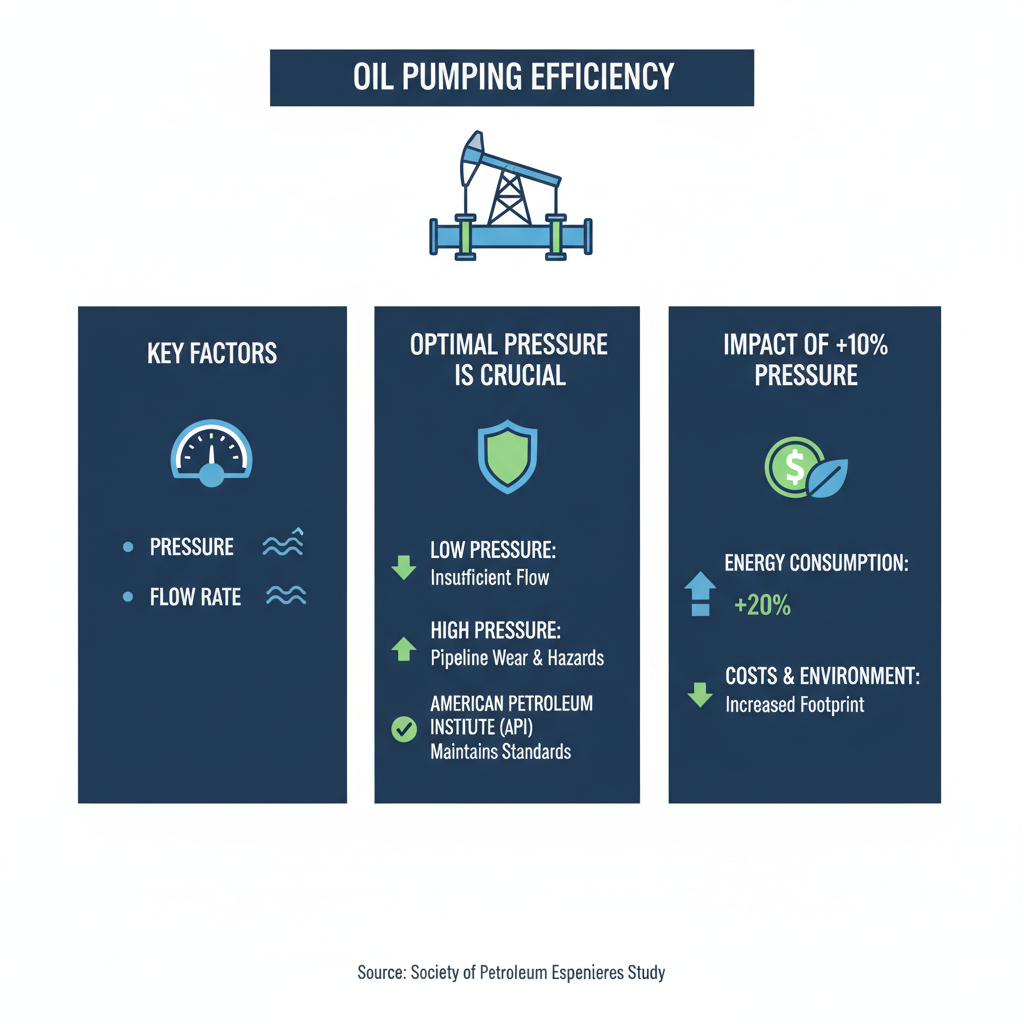

Key Factors Affecting Oil Pumping Efficiency: Pressure and Flow Rate

The efficiency of oil pumping operations is heavily influenced by key factors

such as pressure and flow rate.

According to the American Petroleum Institute, maintaining optimal pressure levels is crucial;

lower pressures can lead to insufficient flow rates, while excessively high pressures can result in

pipeline wear and safety hazards. For instance, a study by the

Society of Petroleum Engineers highlights that a sustained pressure increase of just 10%

can increase energy consumption by up to 20%, impacting both operational costs and

environmental sustainability.

Flow rate also plays a significant role in maximizing pumping efficiency.

A report from the Energy Information Administration states that achieving the ideal flow rate not only

minimizes energy usage but also prevents turbulence that can cause cavitation—a

condition that may damage pump components over time. Properly calibrated flow rates ensure that the system operates

within its designated parameters, leading to increased longevity and reduced maintenance costs. Furthermore, optimizing

both pressure and flow rate in tandem has been shown to improve overall production rates, emphasizing the importance of

careful monitoring and adjustment in oil pumping operations.

Safety Protocols in Oil Pumping: Preventing Spills and Accidents

When it comes to oil pumping, safety should always be a top priority. Implementing robust safety protocols is essential to prevent spills and accidents that can have devastating consequences for both the environment and personnel. Regular training for workers on emergency procedures and proper equipment handling can significantly reduce risks. Moreover, using advanced monitoring systems allows for real-time tracking of operations, providing professionals with the tools they need to react swiftly to any irregularities.

Tips: Always conduct routine inspections of equipment and pipelines to identify potential leaks or weaknesses. Establish a clear communication plan among team members, ensuring everyone knows their roles in the event of an emergency. Regularly update safety drills to keep everyone prepared and informed about the latest safety measures.

Adhering to stringent safety measures not only protects workers but also enhances overall operational efficiency. Regularly reviewing and updating safety protocols in accordance with industry standards can further mitigate risks. Utilizing spill containment solutions and creating designated zones for hazardous materials are also crucial steps to maintain a safe working environment.

Maintenance Practices for Oil Pumps: Ensuring Longevity and Reliability

Proper maintenance practices for oil pumps are crucial for ensuring their longevity and reliability. Regular inspection should be the cornerstone of any maintenance routine, allowing for early detection of wear and tear on components such as seals, bearings, and impellers. By keeping an eye on these parts, operators can replace them before they lead to bigger, more costly failures. Additionally, checking for leaks and ensuring that all fittings are secure can prevent loss of oil and environmental hazards.

Lubrication is another vital aspect of oil pump maintenance. Using the right type and amount of lubricant minimizes friction and reduces heat levels, which can otherwise cause premature damage. It’s important to follow the manufacturer’s guidelines regarding lubrication schedules and types of lubricants. Furthermore, operators should monitor oil quality regularly, as contaminated oil can severely impact pump performance and reliability. Implementing a routine maintenance schedule that includes thorough cleaning and testing can significantly enhance the efficiency and safety of oil pump operations.

Utilizing Technology in Oil Pumping: Automation and Monitoring Systems

In the context of oil pumping, the integration of automation and advanced monitoring systems plays a crucial role in enhancing both efficiency and safety. The implementation of smart technologies, such as robotic systems, has revolutionized various operations within the energy sector. For instance, automated drilling systems and intelligent oil platforms have shown significant improvements in deep-water operations, allowing for precise control and real-time data analysis. This not only boosts productivity but also minimizes the risks associated with manual interventions, which is vital for maintaining safety standards in challenging environments.

Moreover, the adoption of Industry 4.0 principles, including the Internet of Things (IoT), is proving to be transformative in the oil and gas industry. By enabling devices and systems to communicate seamlessly, operators can monitor equipment performance, predict maintenance needs, and optimize resource allocation, resulting in cost reductions and improved operational reliability. The emergence of artificial intelligence in monitoring and control systems further enhances the efficiency of extraction and pumping processes, ensuring that energy resources are utilized sustainably while meeting the growing demands of the market.

How to Effectively Pump Oil for Maximum Efficiency and Safety - Utilizing Technology in Oil Pumping: Automation and Monitoring Systems

| Parameter | Importance | Typical Values | Automation Technology |

|---|---|---|---|

| Flow Rate (bbl/day) | High | 500 - 5000 | Flow Meters |

| Pressure (psi) | Critical | 50 - 2000 | Pressure Sensors |

| Temperature (°F) | Moderate | 50 - 200 | Temperature Sensors |

| Vibration Level (g) | High | 0.1 - 1.0 | Vibration Monitors |

| Downtime (hours/month) | Low | 0 - 10 | Predictive Maintenance Systems |

Related Posts

-

Understanding the Future of Energy: How Oil Pumps Power the Transition to Renewable Resources

-

Why Oil Pumps Are Essential for Efficient Fluid Management in Industrial Applications

-

Maximizing Efficiency: The Impact of Industrial Vacuum Blowers on Energy Consumption in Manufacturing

-

Understanding the Importance of Septic Vacuum Pumps for Effective Waste Management Systems

-

2025 Top 5 Suction Pumps: Best Picks for Efficiency and Reliability

-

What is Vacuum Oil and How it Benefits Industrial Applications