- Eng

- Deu

- Fra

10 Essential Tips for Choosing the Right Vacuum Blower Pump for Your Needs

Choosing the right vacuum blower pump is pivotal for ensuring efficiency and performance across various applications, from industrial processes to environmental management. According to a report by the International Association of Vacuum Blower Pump Manufacturers, the global market for vacuum blower pumps is projected to reach $2.5 billion by 2025, reflecting a compound annual growth rate of 6.3%. This surge indicates the growing importance of selecting the appropriate equipment for specific operational needs, emphasizing the need for informed choices in this sector.

Industry expert Dr. Emily Thornton, a leading authority in fluid mechanics, states, "The right vacuum blower pump can significantly enhance productivity and reduce operational costs." This sentiment resonates within the industry, as different models and specifications cater to varying demands. Understanding the key factors influencing the selection process is crucial not only for optimizing performance but also for minimizing wear and tear on machinery, which can lead to substantial savings over time. By taking into account these essential tips, businesses can make educated decisions that align with their unique requirements and operational goals.

Key Factors to Consider When Selecting a Vacuum Blower Pump

When selecting a vacuum blower pump, several key factors must be considered to ensure optimal performance and efficiency for your specific application. Firstly, the pump's capacity and pressure requirements are critical. According to a report by MarketsandMarkets, the vacuum pump market is projected to reach $3.1 billion by 2026, with growth driven by high demand in industries such as food packaging and pharmaceuticals. Understanding the required vacuum level and the volume of air the pump must displace is essential for determining the right model.

Another important aspect is the pump's operating environment. Different vacuum blower pumps are designed to operate under various conditions, including temperature extremes and the presence of corrosive materials. An analysis from TechSci Research highlights that the shift towards energy-efficient vacuum solutions is influencing design innovation. Pumps crafted from materials resistant to wear and corrosion, such as stainless steel or specialized polymers, ensure longevity and reliability in challenging settings. Additionally, ease of maintenance and noise levels should also be reviewed, as these factors can significantly impact overall operational efficiency and workplace comfort.

Understanding the Different Types of Vacuum Blower Pumps Available

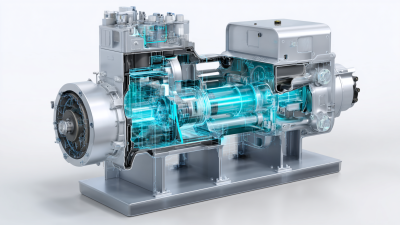

When selecting a vacuum blower pump, understanding the different types available is crucial to meet your specific needs. Vacuum blower pumps can primarily be categorized into positive displacement pumps and kinetic pumps. Positive displacement pumps, such as rotary vane and diaphragm pumps, excel at providing a consistent suction level, making them ideal for applications requiring precise vacuum levels. These pumps work by trapping a specific volume of air and displacing it, ensuring excellent reliability in a variety of industrial and commercial setups.

On the other hand, kinetic pumps, such as centrifugal and side channel blowers, utilize high-speed impellers to transfer energy to the air, creating vacuum pressure. These pumps are particularly advantageous for processes that necessitate high flow rates or rapid evacuation of air. Understanding the fundamental differences between these types allows users to assess their application requirements better, such as the required vacuum level, flow rate, and maintenance preferences. Each type has its strengths and weaknesses, making it essential to align your choice with your operational objectives for optimal performance.

Vacuum Blower Pump Types and Their Applications

Assessing the Pump's Performance Specifications and Efficiency Ratings

When selecting a vacuum blower pump, it's crucial to assess the pump's performance specifications and efficiency ratings to ensure it meets your specific needs. Start by examining the pump's flow rate and ultimate vacuum level. A higher flow rate indicates the pump's ability to move air quickly, while the ultimate vacuum level reveals how effectively it can remove air or gas from a sealed environment. Look for models that offer performance curves; these graphical representations can help you understand how the pump performs under various operating conditions.

Another important consideration is the efficiency rating of the pump. High-efficiency models can significantly reduce operational costs and energy consumption. Look for pumps that are rated for their power consumption relative to their performance output. Tip: Always check for user reviews and industry ratings to gauge real-world performance, as published specs may not fully reflect everyday use. Additionally, choose a pump with reliable components and ease of maintenance to ensure longevity and optimal performance.

Evaluating the Pump's Maintenance Requirements and Durability

When selecting the right vacuum blower pump, understanding its maintenance requirements and durability is crucial. A vacuum blower pump that is difficult to maintain can lead to increased downtime and reduced efficiency. Prioritize models that offer easy access to critical components for routine checks and servicing. Consider whether the pump has features such as self-lubrication or oil-free operation, which can significantly reduce maintenance tasks. Regularly scheduled maintenance should be straightforward, ideally supported by the manufacturer’s guidelines that detail necessary service intervals.

Durability is another vital factor in pump selection. Look for pumps made from high-quality materials that can withstand the conditions of your specific application. Pumps designed for heavy-duty use tend to have longer lifespans and require less frequent replacement. Additionally, check for warranties or guarantees from the manufacturer, as these can provide insights into the pump’s expected durability. By focusing on both maintenance and durability, you can ensure that your investment in a vacuum blower pump delivers long-term reliability and performance.

Budget Considerations: Finding a Quality Vacuum Blower Pump Within Your Price Range

When searching for the right vacuum blower pump, budget considerations play a pivotal role. It's essential to determine your price range upfront, as this will significantly narrow down your options and help you avoid overspending. Look for models that offer the best value, rather than simply choosing the cheapest option. A good rule of thumb is to balance features and reliability against cost. Investing a bit more in a high-quality model can save you money in the long run by reducing repair costs and downtime.

Another important tip is to research the specifications you need. Different applications may require different levels of power and efficiency. For instance, smaller tasks might only need a less powerful vacuum blower, while industrial applications might require a robust unit. Comparing prices based on the features you need can prevent you from paying for unnecessary extras. Additionally, don’t overlook additional costs such as maintenance and operational efficiency, which can affect your overall budget. By prioritizing your requirements and aligning them with your budget, you can find a vacuum blower pump that meets your needs without breaking the bank.

| Tip Number | Tip Description | Price Range (USD) | Key Features |

|---|---|---|---|

| 1 | Determine your vacuum needs based on application | $100 - $300 | High suction power, suitable for industrial use |

| 2 | Consider the size and portability of the pump | $150 - $400 | Compact design, lightweight, easy to transport |

| 3 | Look for energy efficiency ratings | $200 - $500 | Low energy consumption, cost-effective operation |

| 4 | Check the noise level during operation | $100 - $350 | Quiet operation, ideal for noise-sensitive environments |

| 5 | Evaluate the warranty and service options | $170 - $450 | Comprehensive warranty, reliable customer service |

| 6 | Research the ease of maintenance | $120 - $400 | User-friendly design, easy to clean and maintain |

| 7 | Consider the material and build quality | $180 - $500 | Durable materials, corrosion-resistant components |

| 8 | Assess additional features and accessories | $200 - $550 | Includes hoses, filters, and attachments |

| 9 | Read user reviews and ratings | $160 - $420 | Insights from real users, performance feedback |

| 10 | Compare prices across different retailers | $150 - $500 | Opportunity to find the best deals and discounts |

Related Posts

-

The Essential Guide to Understanding Vacuum Pumps for Everyday Use

-

The Essential Guide to Understanding Oil Vacuum Pumps and Their Applications in Industry

-

Exploring the Efficiency of Vacuum Pumps: A Deep Dive into Applications and Performance Metrics

-

2025 Top 5 Vacuum Blower Pumps to Boost Your Industrial Efficiency

-

7 Essential Tips for Choosing the Best Suction Pump for Your Needs

-

Exploring Vacuum Oil: Key Benefits and Industry Trends Influencing Machinery Performance