Top Strategies for Maximizing Efficiency with the Best Rewinding Machine in Your Production Line

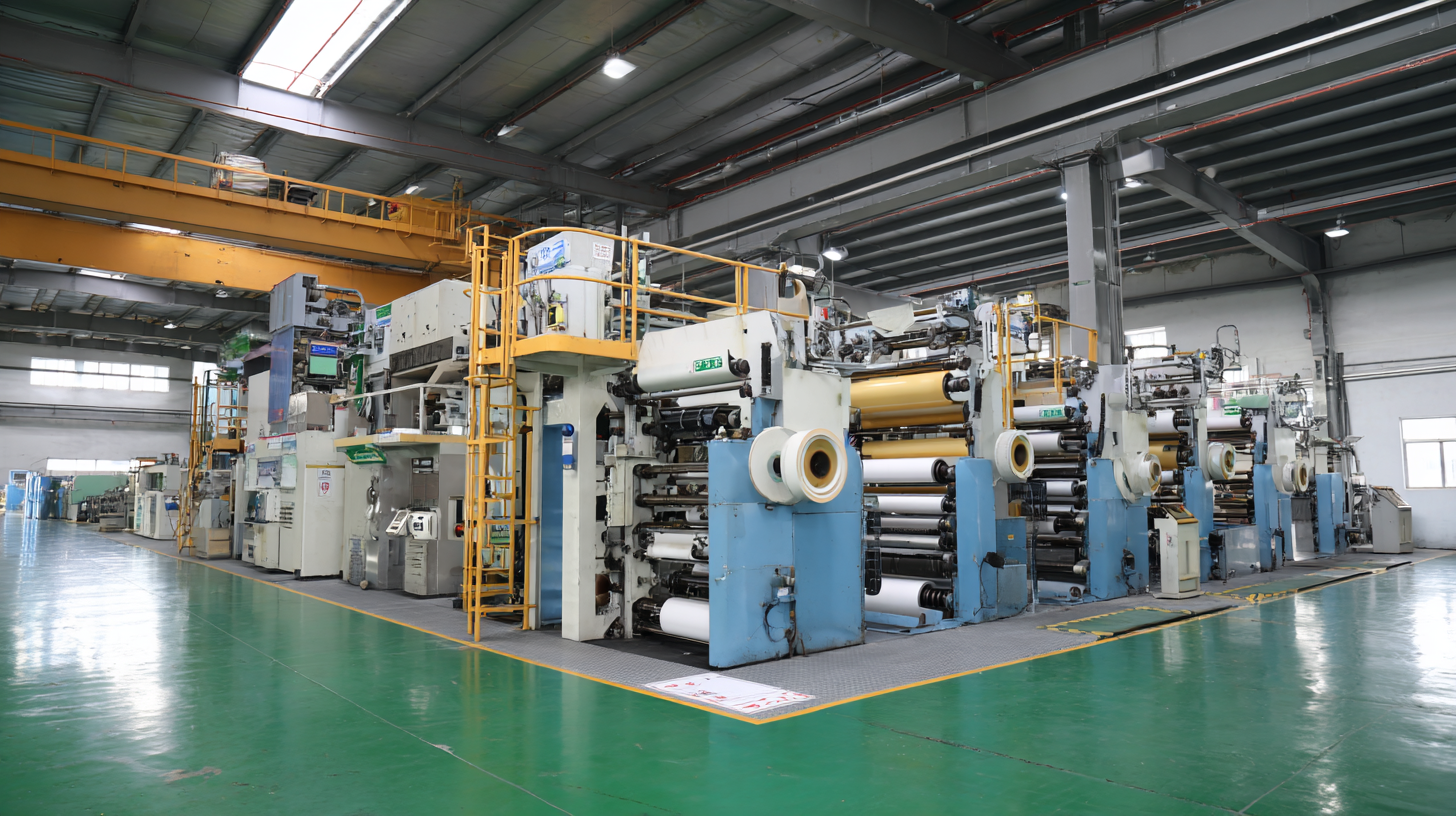

In the fast-paced manufacturing environment, optimizing operational efficiency is crucial for success. One of the key components that can significantly enhance productivity in production lines is the Rewinding Machine. According to a report by Smithers Pira, the global market for rewinding machines is projected to grow at a compound annual growth rate (CAGR) of 4.5%, driven by increasing demands in the packaging and printing industries. Furthermore, industry experts suggest that effective use of advanced rewinding machines can improve production speed by up to 30%, while also reducing material waste by as much as 15%. This blog will explore top strategies for maximizing efficiency with the best rewinding machines, providing insights for businesses looking to streamline their operations and enhance their bottom line.

Top Benefits of After-Sales Service for Rewinding Machines in Production Lines

When investing in a rewinding machine for your production line, the importance of after-sales service cannot be overstated. A reliable after-sales support system ensures that any operational hiccups are swiftly addressed, minimizing downtime and maintaining productivity. Technicians who are well-versed in the machinery can provide critical guidance for proper maintenance, troubleshooting technical issues, and optimizing machine performance. This not only enhances the machine’s longevity but also supports the overall efficiency of the production line.

Moreover, having access to continuous training and updates from the manufacturer can significantly bolster your team’s skills and knowledge. This empowers operators to fully utilize the rewinding machine's features, leading to improved output and less material waste. Additionally, strong after-sales service can lead to better spare parts availability, ensuring that your production line remains uninterrupted, especially when quick repairs are required. By prioritizing after-sales service, companies can create a more resilient production process that is capable of adapting to growing demands in a competitive market.

Cost Analysis: Understanding the Repair Costs of Rewinding Machines in Different Scenarios

When evaluating the cost of repairing rewinding machines in various manufacturing scenarios, it’s crucial to analyze the relationship between the total repair costs and production volume. In high-volume production environments, the wear and tear on equipment can significantly increase repair expenses. Understanding this dynamic allows manufacturers to make informed decisions about maintenance schedules and how repairs impact overall operational efficiency.

Moreover, the choice of materials used in production processes can influence the effectiveness of rewinding machines. As composite materials gain traction in the market for their combination of performance and cost-effectiveness, manufacturers must consider how these materials can minimize wear and extend the lifespan of their machinery. This can result in lower repair costs over time, allowing for a more efficient allocation of resources within the production line. Recognizing the link between production materials and equipment longevity is essential for maximizing efficiency and minimizing unexpected expenses.

Case Studies: Successful Implementations of Rewinding Machines and Their Impact on Efficiency

In recent years, numerous industries have witnessed transformative results through the implementation of advanced rewinding machines. One notable case study comes from a leading packaging company that integrated a high-speed rewinding machine into its production line. By optimizing their workflow, they achieved a 30% reduction in waste and substantially increased output rates. The machine’s precision and reliability allowed for consistent production quality, ultimately leading to heightened customer satisfaction and repeat business.

Another compelling example is found in the textile industry, where a manufacturer adopted a state-of-the-art rewinding machine to enhance their fabric processing. This implementation not only streamlined their operations but also enabled them to meet tight deadlines without compromising on quality. The improved efficiency translated into significant cost savings and allowed the company to expand its market reach. These case studies illustrate how strategically leveraging rewinding machines can drive substantial improvements in operational efficiency, helping businesses stay competitive in an increasingly demanding market.

Top Strategies for Maximizing Efficiency with the Best Rewinding Machine in Your Production Line

| Case Study | Type of Rewinding Machine | Production Line Enhancement | Efficiency Improvement (%) | Remarks |

|---|---|---|---|---|

| Case Study 1 | Inline Rewinding Machine | Reduced material waste | 25% | Improved product quality |

| Case Study 2 | Automated Slitting Rewinder | Increased production speed | 40% | Reduction in labor costs |

| Case Study 3 | Tension Control Rewinding Machine | Consistent product sizing | 30% | Less downtime |

| Case Study 4 | High-Speed Rewinding Machine | Improved output consistency | 50% | Enhanced operational efficiency |

Key Metrics: Analyzing Downtime and Maintenance Efficiency of Rewinding Equipment

In the fast-paced manufacturing landscape, the efficiency of rewinding machines has become a critical aspect of overall operational productivity. According to a recent industry report by Smithers Pira, downtime in production lines can lead to significant losses, with studies indicating that unplanned downtime can cost manufacturers up to $260,000 per hour. Thus, analyzing the performance metrics of rewinding equipment is essential for minimizing interruptions and enhancing throughput.

Key metrics to focus on include machine availability, which is defined as the percentage of time the equipment is operational compared to the total scheduled time. Industry benchmarks suggest that top-performing facilities achieve availability rates above 90%. Additionally, maintenance efficiency plays a vital role, with predictive maintenance strategies reducing downtime by up to 25%, as highlighted in the maintenance best practices report by Deloitte. Implementing regular performance assessments and condition monitoring can empower production managers to identify inefficiencies and address potential failures before they become costly issues.

By focusing on these metrics, manufacturers can not only enhance the reliability of their rewinding machines but also improve overall production efficiency, leading to a more streamlined operation and reduced operational costs. Leveraging data analytics and performance tracking will help ensure that every component of the production line is working optimally.

Industry Trends: How Upgraded Rewinding Machines Enhance Overall Production Line Performance

In today's rapidly evolving manufacturing landscape, upgraded rewinding machines are essential for enhancing overall production line performance. These machines not only improve efficiency but also contribute to better product quality. As industries strive for higher throughput, investing in advanced technology allows manufacturers to stay competitive. One key trend is the integration of automation features that streamline the rewinding process, minimizing downtime and ensuring consistent output.

Tips for maximizing efficiency include regularly maintaining the rewinding machines to prevent breakdowns that can disrupt production. Implementing real-time monitoring systems can provide insights into machine performance, helping identify potential issues before they escalate. Additionally, training staff on the latest machine capabilities ensures that operators can fully leverage the technology, leading to optimized workflow and reduced waste.

Moreover, consider incorporating smart technology that allows for seamless communication between different stages of the production line. By creating an interconnected environment, manufacturers can enhance data flow and decision-making processes, ultimately resulting in a more agile production system. Embracing these industry trends is crucial for businesses aiming to boost their efficiency and maintain a competitive edge.