- Eng

- Deu

- Fra

What is a Vacuum Blower Pump and How Does It Work in Industry

In the dynamic landscape of industrial machinery, the vacuum blower pump emerges as a critical component, playing a vital role in various applications, from material handling to environmental control. According to Dr. Emily Harper, a leading expert in pneumatic systems, "The efficiency of a vacuum blower pump can dramatically influence the operational capabilities of an industrial facility." This statement underscores the importance of understanding not just what vacuum blower pumps are, but also how they operate within complex systems.

At its core, a vacuum blower pump operates by creating a significant pressure difference, enabling the movement of air and other gases in a controlled manner. Through intricate mechanical processes, these pumps facilitate the transport and manipulation of materials in industries ranging from food processing to pharmaceuticals. Understanding the operational principles and applications of vacuum blower pumps is essential for engineers and facility managers seeking to enhance productivity and efficiency.

As industries continue to innovate and evolve, the role of the vacuum blower pump becomes increasingly prominent. By optimizing design and operation, companies can leverage these powerful machines to streamline processes, minimize downtime, and improve overall operational effectiveness. As we delve deeper into the mechanics and uses of vacuum blower pumps, it becomes clear that their impact is felt across a multitude of sectors, redefining standards of efficiency in industrial practices.

What is a Vacuum Blower Pump?

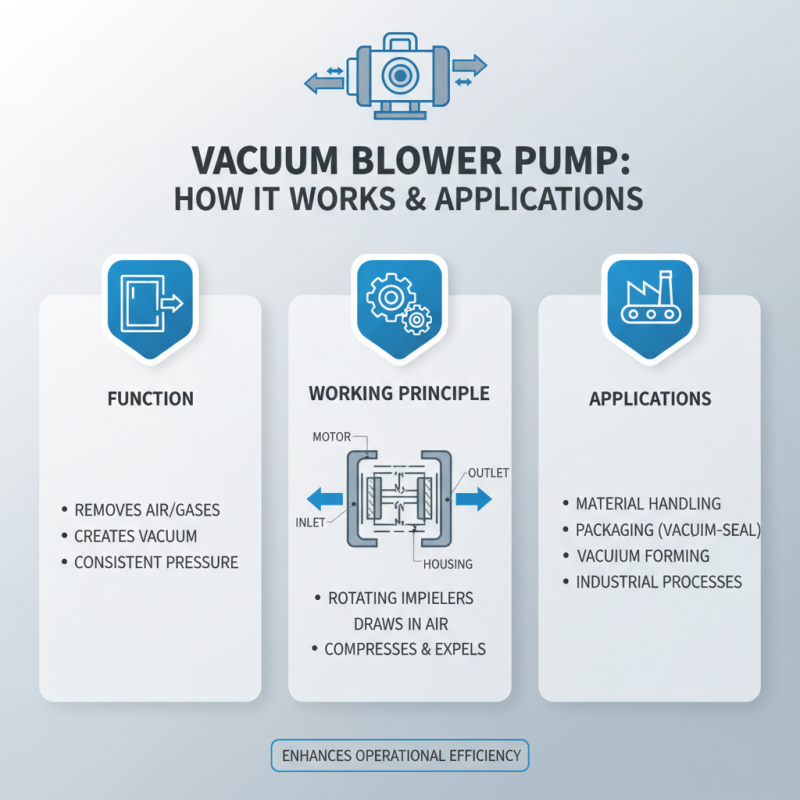

A vacuum blower pump is a mechanical device designed to remove air and other gases from a sealed environment, thus creating a vacuum. These pumps are widely used in various industrial applications due to their ability to maintain consistent vacuum levels and enhance operational efficiency. Typically, a vacuum blower pump works by using a series of rotating impellers within a housing, which draws in ambient air and compresses it, subsequently expelling it from the system. This process results in a significant reduction in pressure within the designated chamber, facilitating operations such as material handling, packaging, and vacuum forming.

In addition to their primary function of creating a vacuum, vacuum blower pumps also play a crucial role in numerous processes across industries. For instance, in food processing, they help in packaging by removing air to extend shelf life. In the woodworking industry, these pumps assist in dust extraction and conveying materials, ensuring a cleaner and safer work environment. By efficiently managing air flow and pressure, vacuum blower pumps contribute to enhancing productivity and product quality in a range of applications, making them an indispensable asset in modern industrial settings.

The Basic Principles of How Vacuum Blower Pumps Work

Vacuum blower pumps are essential tools in various industrial applications, functioning based on the principle of creating a difference in pressure to move gases. These pumps employ direct displacement through rotating elements, effectively reducing atmospheric pressure to generate a vacuum. According to the Global Vacuum Pump Market report, the demand for vacuum pumps, including blower types, is expected to grow at a compound annual growth rate (CAGR) of 5.6% from 2023 to 2030, reflecting their increasing significance in sectors such as manufacturing, food processing, and environmental technology.

The basic operation of a vacuum blower pump involves the intake of air or gas and its subsequent compression or displacement through a series of mechanisms—often including lobes or rotors. As these components rotate, they trap air and push it out of the discharge port, thus creating a vacuum in the intake chamber. Data from industry analyses indicates that vacuum systems can achieve pressures as low as 0.1 mbar, making them crucial for processes that require strict contamination control or material handling in packaging and pharmaceuticals. The efficiency and reliability of these pumps are vital for maintaining operational productivity and ensuring quality control across various manufacturing processes.

Key Components of Vacuum Blower Pumps in Industrial Applications

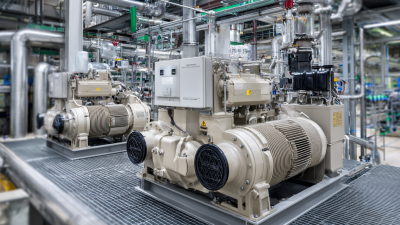

In industrial applications, vacuum blower pumps serve as essential components for various processes, including material handling, packaging, and conveying systems. The key components of these pumps include the blower unit, motor, and filtration system. The blower unit generates the vacuum by creating a pressure difference, allowing for the efficient movement of air and other gases. According to recent industry reports, vacuum pumps account for a significant share of the global market, projected to reach USD 3.25 billion by 2026, driven by their increasing use in sectors such as food processing and pharmaceuticals.

The motor plays a critical role in powering the blower unit, ensuring that it operates effectively under varying loads. In modern industrial systems, these motors are often integrated with variable frequency drives (VFDs) to optimize energy consumption and extend the equipment's lifespan. Furthermore, an efficient filtration system is necessary to prevent contaminants from entering the pump, thereby maintaining operational integrity and reducing downtime. An estimated 30% of maintenance costs in industrial settings can be attributed to failures related to inadequate filtration, highlighting the importance of incorporating robust filtration solutions in vacuum blower pump design.

Vacuum Blower Pump Applications in Industry

Applications of Vacuum Blower Pumps Across Various Industries

Vacuum blower pumps play a crucial role in various industrial applications by creating a vacuum that facilitates processes across different sectors. These pumps are often utilized in material handling, packaging, and environmental management. According to a report by Market Research Future, the global market for vacuum pumps is expected to reach approximately USD 5 billion by 2027, driven by their increasing adoption in industries such as food processing, pharmaceuticals, and semiconductor manufacturing. These industries rely on vacuum technology for efficient and reliable operations, particularly in processes like material conveyance, where vacuum systems help in transferring bulk materials without the risk of contamination.

In the food processing industry, vacuum blower pumps are essential for packaging applications, ensuring that products maintain freshness and quality. The ability to remove air from packaging not only extends shelf life but also enhances product integrity. Reports indicate that the demand for vacuum packaging technology is growing rapidly, with the global market projected to grow at a CAGR of 4.5% through 2025. Similarly, in pharmaceuticals, vacuum systems are pivotal in the manufacturing process, particularly in lyophilization, where moisture is removed under vacuum conditions to preserve sensitive compounds. The pharmaceutical sector's dependence on vacuum technology is reflected in its continuous investment in advanced vacuum systems to ensure compliance with stringent safety standards and improve production efficiency.

What is a Vacuum Blower Pump and How Does It Work in Industry - Applications of Vacuum Blower Pumps Across Various Industries

| Industry | Application | Key Benefits |

|---|---|---|

| Food and Beverage | Vacuum packaging of products | Extended shelf life, reduced food spoilage |

| Pharmaceutical | Drying of active ingredients | Improved product stability and efficacy |

| Plastics | Material handling and pneumatic conveying | Reduced material waste, efficient production |

| Printing | Vacuum feeding of paper into presses | Increased printing speed and accuracy |

| Electronics | Solder paste application in PCB assembly | Improved precision, reduced production costs |

| Environmental | Vacuum collection of waste and dust | Enhanced cleanup efficiency, reduced air pollution |

Advantages of Using Vacuum Blower Pumps for Industrial Processes

Vacuum blower pumps have become increasingly essential in various industrial processes due to their efficiency and reliability. These pumps are designed to create a vacuum by removing air or gas from a sealed space, which is crucial for applications such as packaging, material handling, and surface cleaning. According to a report from the International Vacuum Industry Association, the use of vacuum technology has grown steadily, with the market projected to reach $4.3 billion by 2025, highlighting the importance of these systems in modern manufacturing.

One of the significant advantages of using vacuum blower pumps is their energy efficiency. Unlike traditional pump systems, vacuum blowers operate with lower energy consumption, which can lead to substantial cost savings over time. A study conducted by the American Council for an Energy-Efficient Economy emphasizes that adopting energy-efficient technologies, including vacuum pump systems, can reduce operational costs by up to 30%. Additionally, these pumps offer enhanced performance, providing consistent vacuum levels necessary for high-quality production standards.

Tip: Regular maintenance and monitoring of vacuum blower pumps can prevent unexpected downtimes and ensure optimal efficiency. Implement automation systems that track performance metrics to identify any deviations early.

Another advantage is their versatility; vacuum blower pumps can be used in a wide range of industrial applications, from food packaging to semiconductor manufacturing. Their ability to adapt to different processes and environments makes them invaluable in achieving operational excellence. As industries continue to focus on sustainability and reducing their carbon footprint, the development of more efficient vacuum systems will likely play a crucial role in meeting these goals.

Tip: Consider upgrading to the latest vacuum technology that offers advanced features like noise reduction and low vibration operation to enhance workplace safety and comfort while maintaining efficiency.

Related Posts

-

The Essential Guide to Understanding Vacuum Pumps for Everyday Use

-

Maximizing Efficiency: The Impact of Industrial Vacuum Blowers on Energy Consumption in Manufacturing

-

What is an Oil Vacuum Pump and How Does it Work for Efficient Operations

-

10 Essential Tips for Choosing the Right Vacuum Blower Pump for Your Needs

-

Exploring the Benefits of Tank Vacuum Systems: A Comprehensive Guide for Homeowners

-

Exploring Vacuum Oil: Key Benefits and Industry Trends Influencing Machinery Performance